Atlas ▪ Bolaite Air Compressor

20 years of service experience

400-169-8060

150-0028-5604

150-0028-5604

Product Center

Mailbox:bolaite-air@139.com

Whole machine:+86 150-0028-5604

Service:+86 152-2164-0839

400:400-169-8060

Shanghai Headquarters: Building 3, 58 Caoli Road, Fengjing town, Jinshan District, Shanghai

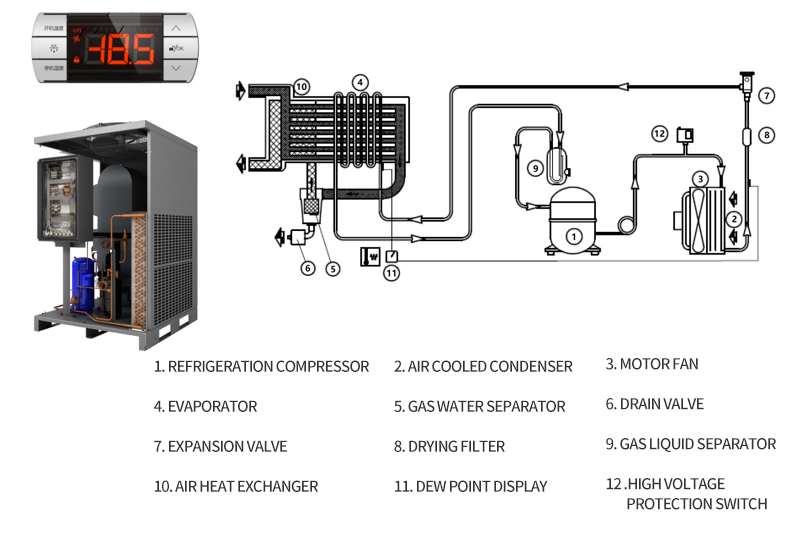

Provide more dry compressed air

L high efficiency three in one plate fin heat exchanger: the temperature difference at the inlet of the cold dryer is as low as 5 ℃

L high efficiency water separator: the water removal efficiency of the cold dry machine reaches 99%

L the relative humidity of compressed air at the outlet is as low as 10%, and there is no pipeline corrosion risk

More energy saving

L compared with the cold dryer with shell and tube heat exchanger, the energy consumption is reduced by 50%

L high efficiency R410A environmental refrigerant

More reliable

L industrial international import brand refrigeration compressor

L new intelligent display, which integrates dew point display and fault alarm

L optimize the pipeline design, only 4 manual welding points, which makes the leakage risk of the cold dryer lower

L before each machine leaves the factory, it shall be tested for three-stage leakage detection of compressed air, helium and refrigerant

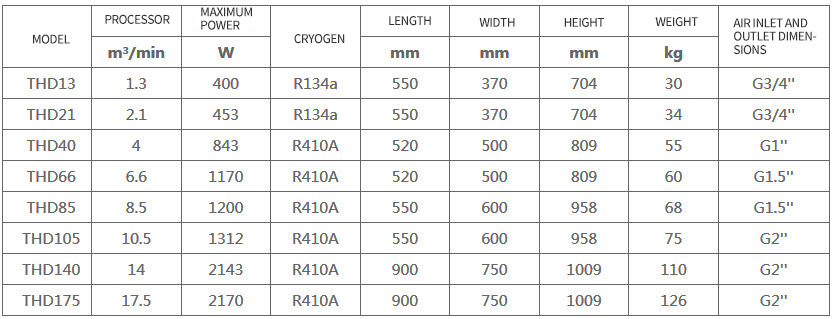

Correction factor of cold dryer

|

ambient temperature |

℃ |

30 |

35 |

40 |

45 |

|

|

|

|

1 |

0.91 |

0.81 |

0.72 |

|

|

|

||

|

Intake air temperature |

℃ |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

|

1 |

1 |

1 |

0.82 |

0.69 |

0.58 |

0.49 |

||

|

Intake pressure |

bar |

6 |

7 |

8 |

10 |

13 |

|

|

|

0.96 |

1 |

1.03 |

1.08 |

1.13 |

|

|

L ambient temperature: ≤ 45 ℃

L inlet temperature: ≤ 60 ℃

L maximum inlet pressure: bld15-225 / blr13-260: 13bar; bld270-1050: 10bar

L power supply: bld15-225 / blr13-260: 230V / 1 / 50 Hz; bld270-1050: 380V / 3 / 50 Hz

L design condition: ambient temperature 30 ℃, inlet temperature 40 ℃.

L maximum pressure drop: less than 0.3bar

Example of cold dryer selection

The rated gas volume of the compressor is 10 m3 / min, and the actual treatment gas volume required under the following conditions:

Ambient temperature: 40 ℃

Intake air temperature: 40 ℃

Intake pressure: 8bar

The actual treatment capacity required is 10 m3 / min / 0.81 / 1 / 1.03 = 12 m3 / min

In order to ensure the pressure dew point, it is necessary to select a cold dryer with a capacity of 12m m3 / min to meet the actual working conditions.

Copyright ©2020 Atlas Bolaite All rights reserved

Technical support:shangyun case number:ICP No.XXXXXXXX