Atlas ▪ Bolaite Air Compressor

20 years of service experience

400-169-8060

150-0028-5604

150-0028-5604

Product Center

Mailbox:bolaite-air@139.com

Whole machine:+86 150-0028-5604

Service:+86 152-2164-0839

400:400-169-8060

Shanghai Headquarters: Building 3, 58 Caoli Road, Fengjing town, Jinshan District, Shanghai

Hotline:

150-0028-5604

Excellent energy efficiency and stable performance

BLT s energy saving series

Benefited from more than 140 years of historical inheritance and technical experience.

Based on the outstanding design ability and rich experience of European group headquarters in air compressors, following the strict development process and test standards of European Group, we strengthen the design for various complex climate and harsh working conditions in China, so as to ensure the most reliable quality guarantee for each BLT series air compressor.

|

High quality core components

Screw engine is just like the heart of screw compressor. Its performance directly affects the energy efficiency and service life of the whole machine. Bolette adopts Atlas Copco engine, the leader of air compressor field. |

|

|

Intelligent control system

7 inch color screen graphic display, touch screen and key control dual mode, simple and convenient operation |

|

|

Electrical system

Standardized design, safe and reliable. |

|

|

Vacuum intake valve

Very low pressure loss, more energy saving. |

|

|

High quality motor

High efficiency design, SKF Bearing, ensure the motor super long life. |

|

|

Efficient and powerful cooling design

Fan and cooler separation design: effectively eliminate the leakage of cooler, and the cooler cleaning and maintenance is more convenient. |

|

|

Pre filtration protection The unique design of pre filter screen cover can keep the whole machine clean, extend the maintenance cycle, make the disassembly and cleaning convenient, and can be reused. |

|

One hundred year inheritance of grade 1 energy efficiency

|

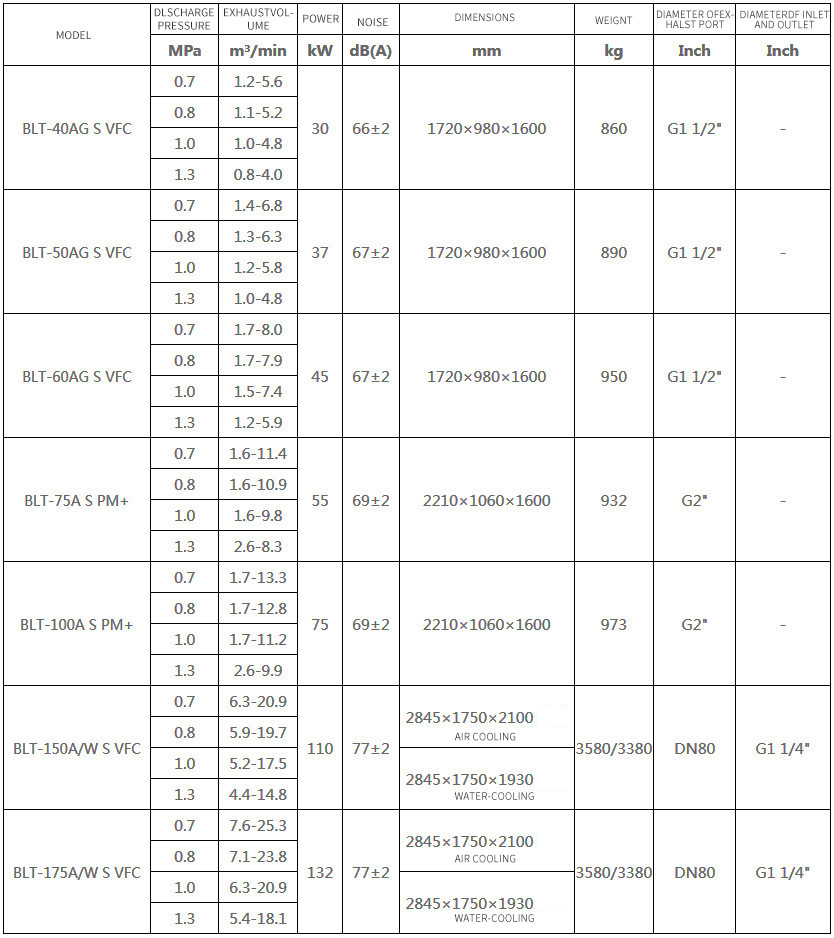

Rated power |

Discharge pressure |

Electricity consumption per cubic meter |

Full load 4000 hours / kWh |

|||

|

MPa |

1级 |

2级 |

3级 |

Energy saving compared with level 2 |

Energy saving compared with level 3 |

|

|

30 |

0.8 |

0.120 |

0.135 |

0.147 |

20000 |

35000 |

|

37 |

0.8 |

0.120 |

0.135 |

0.147 |

24000 |

43000 |

|

45 |

0.8 |

0.120 |

0.135 |

0.147 |

30000 |

54000 |

|

55 |

0.8 |

0.108 |

0.122 |

0.138 |

33300 |

75000 |

|

75 |

0.8 |

0.108 |

0.122 |

0.138 |

45000 |

102000 |

|

110 |

0.8 |

0.105 |

0.118 |

0.135 |

64000 |

149000 |

|

132 |

0.8 |

0.105 |

0.118 |

0.135 |

78000 |

180000 |

Perfect combination of main engine and high efficiency permanent magnet motor

|

BLT PM + permanent magnet variable frequency compressor The combination of the newly launched Atlas Copco main engine and high-efficiency permanent magnet motor, the mature split direct drive system, and the disadvantages of no integrated permanent magnet variable frequency compressor, such as inconvenient disassembly and easy demagnetization, pursue the ultimate efficiency and ensure the high reliability of the compressor.

|

|

|

New host Atlas Copco host specially developed for frequency conversion technology can still maintain high efficiency operation in a wide frequency range and reach the national level 1 energy efficiency standard in the main frequency range.

|

|

|

Permanent magnet high efficiency motor

Ipi55 protects the fully enclosed motor to prevent the dust from being absorbed by the magnetic steel of the motor.

|

|

|

Large touch controller

Matching frequency converter customized.

|

|

|

Direct drive

1: 1 direct drive, stable and efficient.

|

|

Frequency conversion VFC - energy saving control

Variable frequency drive: energy saving control

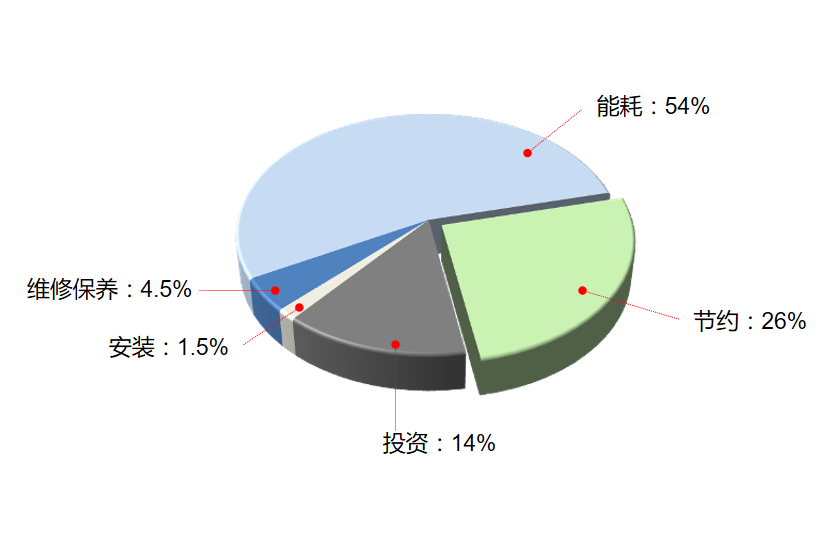

The energy consumption cost of the air compressor generally accounts for about 82% of the overall cost of the service cycle, and the electricity cost of the air compressor may be as high as 40% of the total electricity cost of the factory. Long term follow-up research has proved that the compressed air demand of most users fluctuates by 40-80% in different days, times or months.

The VFC variable frequency air compressor with advanced technology of Bolet can accurately meet the air demand of users. When the user's gas consumption is reduced, the rotation speed is reduced, the exhaust volume is reduced correspondingly, and the energy consumption is also reduced in proportion. Through the advanced frequency conversion technology, the unloading of the compressor is greatly reduced, and the energy consumption is greatly reduced.

The average energy saving can reach 30% or more

Bolet variable frequency air compressor can track the change of air demand and automatically adjust the motor speed, with an average energy saving of 30% or more. The additional cost of investment in VFC variable frequency air compressor can be recovered within 1 to 2 years.

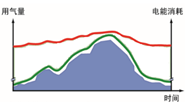

Ordinary model: fluctuating air demand, high cost

Ordinary air compressor sets a wide pressure to deal with the fluctuation of air demand. When the air load is high, it is loaded and unloaded. As a result, the pressure of the system is high and the energy consumption is high. Due to the fluctuation of air demand, the compressor is unloaded for a long time, which leads to the waste of energy consumption.

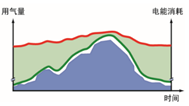

VFC frequency conversion: variable flow, energy saving control

The working pressure set by the variable frequency air compressor is the pressure required by the customer. The pressure of the whole system is low. Because the variable speed can be adjusted to meet the demand of the customer when the load is low, there is almost no unloading, so there is no unnecessary energy consumption.

Optional configuration

|

Optional configuration |

Industrial grade BLT150-350A/W S |

Professional level BLT200-475A/W |

|

Heavy duty nano air filter |

N/A |

Y |

|

Ultra heavy duty nanofiltration system |

Y |

Y |

|

Electric machinery |

IE3 electric machinery |

IE3 electric machinery |

|

Schneider soft starter |

Y |

Y |

|

Presentation materials in English (manual + Parts Manual) |

Y |

Y |

|

Standard factory test report + factory acceptance |

Y |

Y |

|

Special factory test report + factory acceptance |

Y |

Y |

|

Export fumigation wood packing box |

Y |

Y |

|

Programmable controller |

SIEMENS |

SIEMENS |

|

8000 hours initial oil loading |

Y |

Y |

|

Multi machine energy saving control system of BEC |

Y |

Y |

Heavy duty nano air filter

Heavy duty air filter is specially designed for high dust, high impurities and other harsh operating environment. It adopts advanced imported nano filter material, which greatly improves the filtration efficiency and is very easy to clean. It can effectively filter dust and impurities, prolong the service life of the air filter element, and protect the oil and gas pipeline system of the main engine.

Advanced heavy duty nano prefiltration system

The ultra heavy duty pre filtration system with advanced imported nanofiltration materials not only has high filtration performance, but also is very easy to clean. It can effectively protect the main engine and oil and gas pipeline system in ultra harsh operation environment such as high dust, high fiber debris, etc., and has irreplaceable excellent performance.

Multi machine energy saving control system of BEC

BEC blette energy saving control system can monitor multiple air compressors, provide central control for the whole compressed air network, real-time monitoring and dynamic management of real-time air pressure system. It can save a lot of electric energy, and recycle the unit, reduce maintenance and downtime, greatly improve the production efficiency of customers.

Betterlink wireless monitoring system

Through the characteristics of the Internet of things, the compressors in different places are connected to the cloud computing platform through the Internet. Users only need to access the Internet to timely monitor the air compressor, view the real-time operation data, energy-saving spatial analysis and historical curve, and greatly improve the management efficiency.

Copyright ©2020 Atlas Bolaite All rights reserved

Technical support:shangyun case number:ICP No.XXXXXXXX