Atlas ▪ Bolaite Air Compressor

20 years of service experience

400-169-8060

150-0028-5604

150-0028-5604

Product Center

Mailbox:bolaite-air@139.com

Whole machine:+86 150-0028-5604

Service:+86 152-2164-0839

400:400-169-8060

Shanghai Headquarters: Building 3, 58 Caoli Road, Fengjing town, Jinshan District, Shanghai

Hotline:

150-0028-5604

Excellent energy efficiency and stable performance

|

BLT fixed frequency series (11-90kw)

|

|

|

High quality core components

|

|

|

Intelligent control system

|

|

|

Electrical system

|

|

|

Modular design

|

|

|

High quality motor

|

|

|

Efficient and powerful cooling design

|

|

|

Pre filtration protection

|

|

|

|

|

|

|

The average energy saving can reach 30% or more

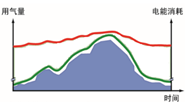

Bolet variable frequency air compressor can track the change of air demand and automatically adjust the motor speed, with an average energy saving of 30% or more. The additional cost of investment in VFC variable frequency air compressor can be recovered within 1 to 2 years.

Ordinary model: fluctuating air demand, high cost

Ordinary air compressor sets a wide pressure to deal with the fluctuation of air demand. When the air load is high, it is loaded and unloaded. As a result, the pressure of the system is high and the energy consumption is high. Due to the fluctuation of air demand, the compressor is unloaded for a long time, which leads to the waste of energy consumption.

Perfect combination of main engine and high efficiency permanent magnet motor

|

BLT PM + permanent magnet variable frequency compressor The combination of the newly launched Atlas Copco main engine and high-efficiency permanent magnet motor, the mature split direct drive system, and the disadvantages of no integrated permanent magnet variable frequency compressor, such as inconvenient disassembly and easy demagnetization, pursue the ultimate efficiency and ensure the high reliability of the compressor.

|

|

|

New host Atlas Copco host specially developed for frequency conversion technology can still maintain high efficiency operation in a wide frequency range and reach the national level 1 energy efficiency standard in the main frequency range.

|

|

|

Permanent magnet high efficiency motor

Ipi55 protects the fully enclosed motor to prevent the dust from being absorbed by the magnetic steel of the motor.

|

|

|

Large touch controller

Matching frequency converter customized.

|

|

|

Direct drive

1: 1 direct drive, stable and efficient.

|

|

Frequency conversion VFC - energy saving control

The working pressure set by the variable frequency air compressor is the pressure required by the customer. The pressure of the whole system is low. Because the variable speed can be adjusted to meet the demand of the customer when the load is low, there is almost no unloading, so there is no unnecessary energy consumption.

Copyright ©2020 Atlas Bolaite All rights reserved

Technical support:shangyun case number:ICP No.XXXXXXXX